Converting an outdated manufacturing plant into a smart factory is an exciting undertaking with enormous potential to boost productivity, competitiveness, and efficiency. Businesses are increasingly looking to update their operations to stay ahead of the curve in today’s fast-paced economic landscape, thanks to technological and automation improvements. Transforming an outdated building into a smart factory not only transforms the production process but also gives companies the ability to respond to changing consumer needs and grasp new expansion prospects.

Evaluating the Facility’s Present Situation

An extensive assessment of the machinery, processes, and infrastructure in place at your manufacturing facility is necessary to determine its current state. Start by taking a close look at the facility’s design and operation, taking into account things like workspace efficiency and space usage. Find any out-of-date or ineffective equipment that could reduce output. Evaluate your operation’s energy usage and environmental impact as well. You can successfully migrate to a smart factory by identifying areas for modernization and improvement by analyzing the strengths and weaknesses of your facility.

Specifying Specific Goals for the Conversion

Achieving success in transforming your manufacturing site into a smart factory requires defining certain goals. Start by outlining precise objectives that complement your overarching business goals, including increasing productivity, cutting expenses, or raising the caliber of your output. Setting up key performance indicators (KPIs) will assist you in tracking developments and evaluating the conversion process efficacy. Ensure that your objectives are realistic and achievable within the given time frame. You can maintain focus and monitor your progress toward developing a more intelligent and competitive manufacturing operation by establishing clear goals early on.

Organizing and creating the layout of the smart factory

To maximize production and efficiency, several things must be carefully considered while planning and developing the layout of your smart factory. Make a thorough layout plan first, incorporating contemporary technology like automation systems, sensors, and Internet of Things devices. Create workflows that make the most use of the available space and reduce bottlenecks. Prioritizing layout flexibility is crucial to allow for future upgrades and modifications to production processes. You may increase total profitability by optimizing processes, decreasing downtime, and carefully designing the layout of your smart factory.

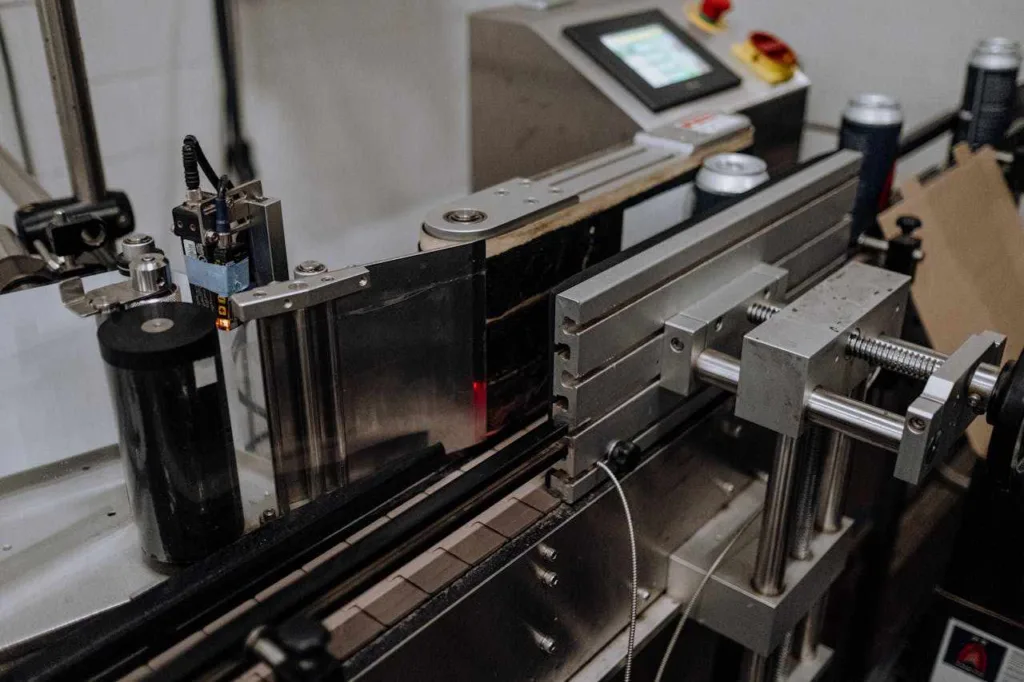

Putting Smart Systems and Technologies into Practice

Integrating a variety of cutting-edge equipment into your production facility is necessary to implement smart technologies and systems that will increase productivity and efficiency. This involves using manufacturing software to optimize workflows, IoT sensors to monitor machinery and processes in real-time, and automation tools to simplify production operations. You may increase overall operational performance and maintain your competitiveness in the quick-paced industrial environment of today by utilizing these smart technologies and systems. Adopting these innovations promotes creativity and sustainability in your operations while also increasing efficiency.

Improving Communication and Connectivity

Establish a strong network architecture that guarantees dependable connectivity between devices and systems to improve connectivity and communication within your manufacturing facility. Put in place secure methods to protect sensitive data from potential cyber threats during data transit and storage. Encourage cooperation between various departments and systems by endorsing interoperability and open lines of communication. You may expedite decision-making procedures, enable real-time data interchange, and raise overall productivity and efficiency in your smart factory by strengthening connectivity and communication.

Educating and Providing for the Workforce

The workforce’s empowerment and training are essential for the smooth transition to a smart factory environment. Provide in-depth training courses so that employees have the skills and knowledge necessary to effectively use and maintain new technologies. Promote a culture of creativity and ongoing education where staff members are encouraged to offer ideas and suggestions for enhancements. Investing in your employees’ training will boost morale, productivity, and engagement—all of which will contribute to the success of your smart manufacturing project.

Conclusion

You may create the conditions for a successful change by evaluating where you are now, establishing specific goals, and creating an effective plan. Increasing connection and integrating smart technologies will simplify processes and boost output. Furthermore, providing thorough training programs to your employees empowers them, encourages innovation, and guarantees seamless transitions to new systems.